HOW TO: ID THREAD IN THE FIELD

Apr 14, 2023

HOW TO ID THREAD IN THE FIELD

A drill pipe thread is a mechanical connection used to join two sections of drill pipe together. It is typically made up of two main components: the male thread, also known as the pin, and the female thread, also known as the box. The male thread has a tapered end that allows it to be inserted into the female thread, which has a corresponding tapered interior. Once inserted, the threads interlock, and the pipe sections or tolling are securely joined.

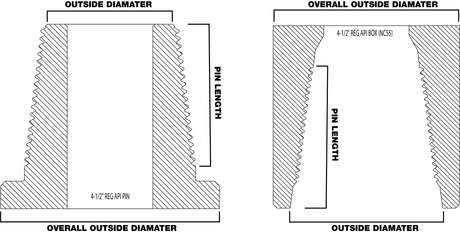

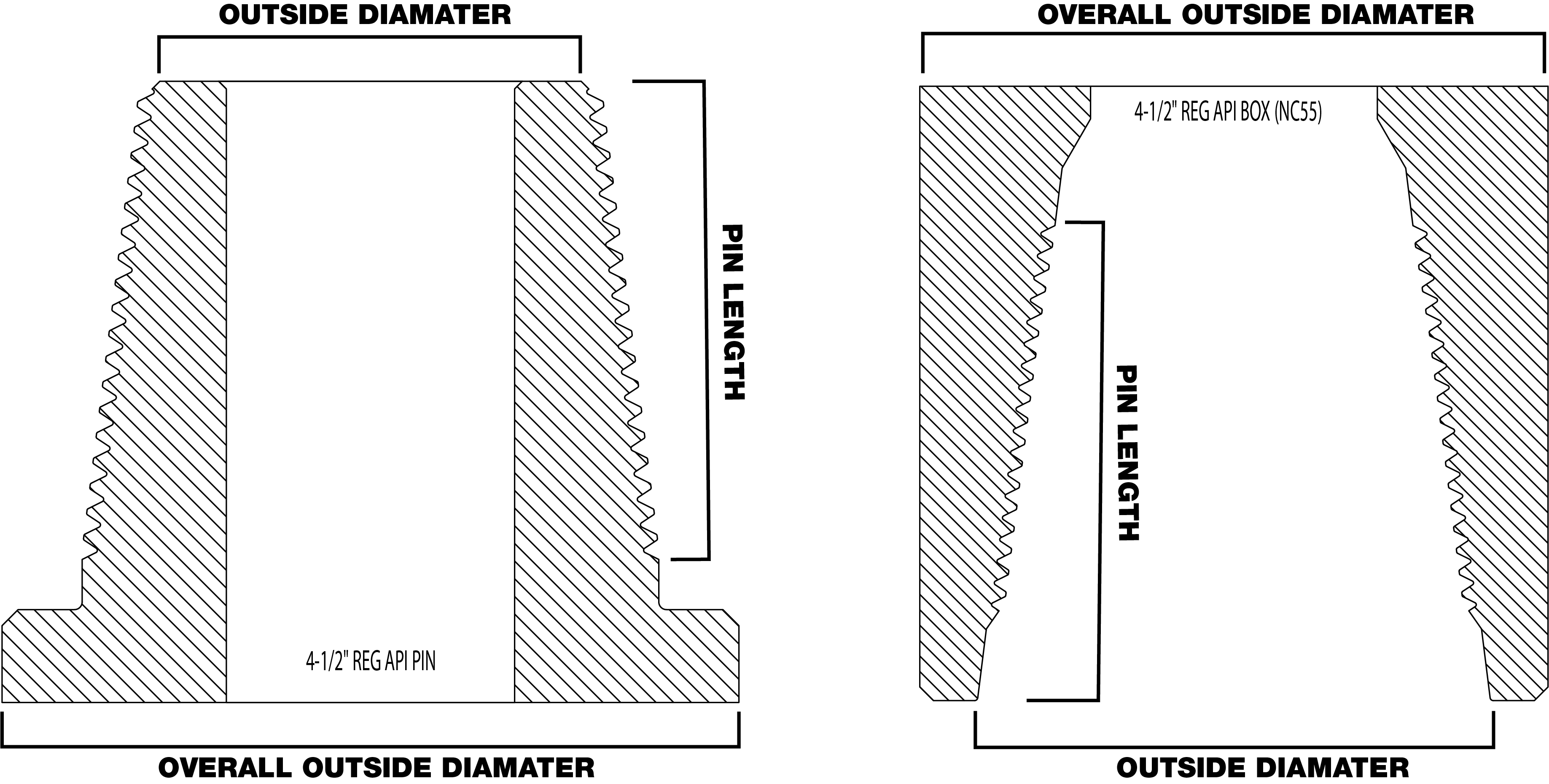

With no standardization of pipe and tooling connections in the HDD industry, it can sometimes be challenging to determine the identity of a thread connection. Say you're in the field and you're needing to order a new tool. Your salesman will ask you what kind of thread you have and what kind of connection. If you don't have a thread identification tool handy and don't know what kind of thread you need, we've laid out the following steps as the best way to identify which thread you have. First, knowing what rig the pipe came from or that the adapter will be used on is helpful in figuring out what thread you will need. There will also be a few measurements needed to help identify the thread: Pin or Box Length, Overall Outside Diameter, and Outside Diameter.

When identifying a thread, you must first determine whether you are staring at the male end or the female end, better known as PIN or BOX. Once the type of end you have is identified, you will then count your total number of threads (this is easier done on a male end or PIN). With a tape measurer, begin your measurement of the overall outside diameter of the thread connection. If you're measuring a box end, your outside diameter will be your shoulder. Once you have your overall outside diameter, you will then measure the length of either the box or pin end. On the box end, you will stick the tape measurer inside the box until you reach the end inside and record that measurement. On the pin end, you will take the top of the tape measurer, all the way to the shoulder of the thread, and record that measurement. Here, you can also measure your threads per inch. This involves counting the number of threads (or peaks) per inch. NOTE – the shoulder of the thread is where the thread stops and the collar begins. Lastly, you will measure the nose of the pin end for your outside diameter.

It's important to note that while these measurement and thread identification tricks work on all rig types, some rigs have certain identifiers that make them more easily identified than others. For instance, Ditch Witch threads always have an elongated tip, also known as the nose. Radius HDD Salesman, Chance Moore, often recites the moniker "If it has a nose, you "knows" it's Ditch Witch" when teaching thread identification to a new salesman and green hats in the field. Ditch Witch thread is predominantly a finer, straight thread that closely resembles the API standard pattern versus the Vermeer threads, which are more often tapered.

The American Petroleum Institute (API) is the only trade association that represents all aspects of America's drilling industry. API IF, or internal flush, is tapered and flat. The IF connections are widely recognized as the strongest connection in the industry, and it is used in most of your downhole applications due to that. API regular connections are a sharp and tapered thread.

In conclusion, identifying pipe and tooling threads in the HDD industry can be a challenge due to the lack of standardization. Additionally, it's important to keep in mind that certain rigs have unique identifiers that can make them easily identifiable. By following these methods and being aware of these identifiers, it is possible to confidently identify a thread connection in the field for any tooling and pipe needs.

You can read this article in Trenchless Technology by clicking HERE!